Behind the Scenes of Lateral Flow Tests: The Role of the Sample Pad

Introduction

Lateral Flow Tests (LFTs) have become a household term in recent years, primarily due to their widespread use in rapid diagnostic testing, including COVID-19 antigen tests. These tests, known for their simplicity, speed, and cost-effectiveness, have revolutionized the field of point-of-care diagnostics, enabling quick and accurate detection of various diseases and conditions.

Lateral Flow Tests (LFTs) have become a household term in recent years, primarily due to their widespread use in rapid diagnostic testing, including COVID-19 antigen tests. These tests, known for their simplicity, speed, and cost-effectiveness, have revolutionized the field of point-of-care diagnostics, enabling quick and accurate detection of various diseases and conditions.

In my previous article, you lerned about the function of the the waste pad. Today, we turn our attention to another component of these tests - the sample pad. It is the entry point for the sample into the test device.

The sample pad's role is multifaceted. It is responsible for the initial application of the sample, whether it be blood, urine, or saliva. It prepares the sample for the test, often containing reagents that adjust the sample's pH, break down cell walls to release antigens, and maintain the sample's ionic strength. It also serves as a transport medium, allowing the sample to migrate from the point of application to the rest of the test device. Furthermore, it can contain substances that block or neutralize substances in the sample that could interfere with the test results.

The performance of LFTs is largely dependent on the quality and characteristics of the sample pad. Therefore, understanding how the sample pad is designed, manufactured, and evaluated is of importance for your assay development. This article aims to provide a compressed overview of the sample pad, its function, the materials used in its manufacturing, and the process of its application and evaluation.

Understanding the Sample Pad

Understanding the Sample Pad - Function

The sample pad plays a vital role in lateral flow tests, often underestimated despite its crucial contribution to the test's overall functionality. It serves as the entry point for the sample into the test device, primarily functioning as a medium for applying the sample to the test.

The sample pad serves several important functions, such as:

- Sample Application: The sample pad is where the sample (e.g., blood, urine, saliva) is applied to the test. It needs to be able to absorb the sample quickly and efficiently.

- Sample Preparation: The sample pad often contains reagents that prepare the sample for the test. These reagents can include buffers to adjust the sample's pH, detergents to break down cell walls and release antigens, and salts to maintain the sample's ionic strength. Filtering out unwanted particles and contaminants from the sample or other undesired components of the sample – for example erythrocytes from whole blood.

- Sample Transport: The sample pad allows the sample to migrate from the point of application to the rest of the test device. This is achieved through capillary action, where the sample is drawn up through the porous material of the sample pad. By the correct choice of material also the volume and speed of the sample delivery can be controlled.

- Blocking Interfering Substances: The sample pad can also contain substances that block or neutralize substances in the sample that could interfere with the test results.

The performance of LFTs depends largely on the quality and characteristics of the sample pad. Therefore, it is essential to understand how the sample pad is designed, manufactured, and evaluated.

Understanding the Sample Pad - Material

The sample pad is typically made of a porous material, such as cellulose, glass fiber, or synthetic polymer. It is industrially generally produced like standard paper. That is, in a solvent evaporation process that generates master rolls with several meters of width and more than 100 meters of length. Those master rolls are then cut into standard sized rolls of for example 2 cm width and 100 Meter length or custom-cut. Another typical commercially available form are sets of sheets of Letter or A4 size.

The material should have high absorbency, wettability, and uniformity to ensure consistent and efficient sample uptake and delivery. The material should also have low background interference and high stability to avoid false positives or negatives.

The thickness, density, pore size, and surface chemistry of the sample pad can affect its performance. For example, thicker and denser pads can hold more sample volume but may slow down the flow rate. Smaller pore sizes can filter out more particles but may also trap some target analytes. Surface chemistry can influence the binding affinity and solubility of the analytes and reagents. It is of absolute essence that for every development different sample pads are evaluated.

The sample pad can also be in-house-modified by impregnation with various substances to improve or alter its functionality. For instance, surfactants can increase the wettability and reduce the surface tension of the pad. Buffers can adjust the pH and ionic strength of the sample to enhance the reaction kinetics. Sugars can enhance signal generation at the test line and also be used for slowing down the overall flow speed – thus potentially increasing sensitivity.

For more details, you should refer to the general manufacturers information like those, to name a few:

Assembly of the Sample Pad

The sample pad is usually applied in LFT manufacturing

-

either directly from roll using a reel-to-reel equipment.

-

or cut in the correct size from a sheet using a sheet slitter or paper cutter

The material can be pre-treated or coated with different substances (surfactants, buffers, sugars, …) by spraying or immersion. The material is then attached to the backing continuously from roll using a reel-to-reel laminator or batch-wise from larger strips by using a manual assembler.

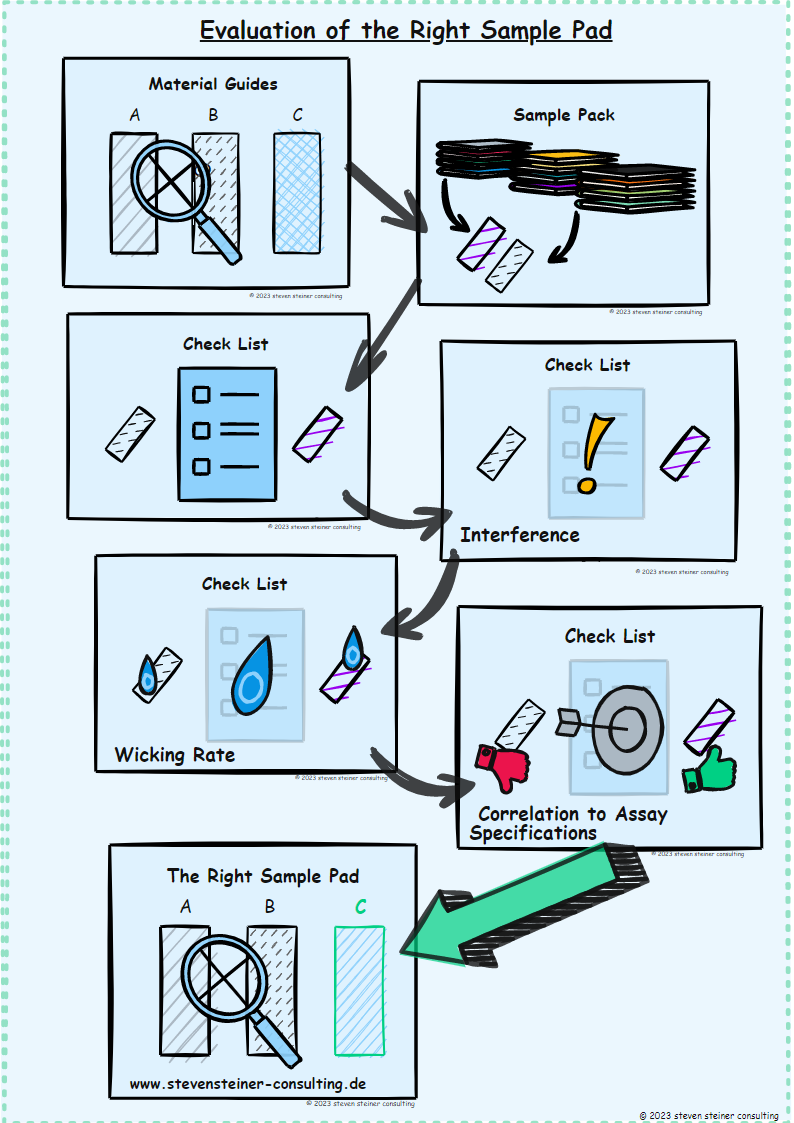

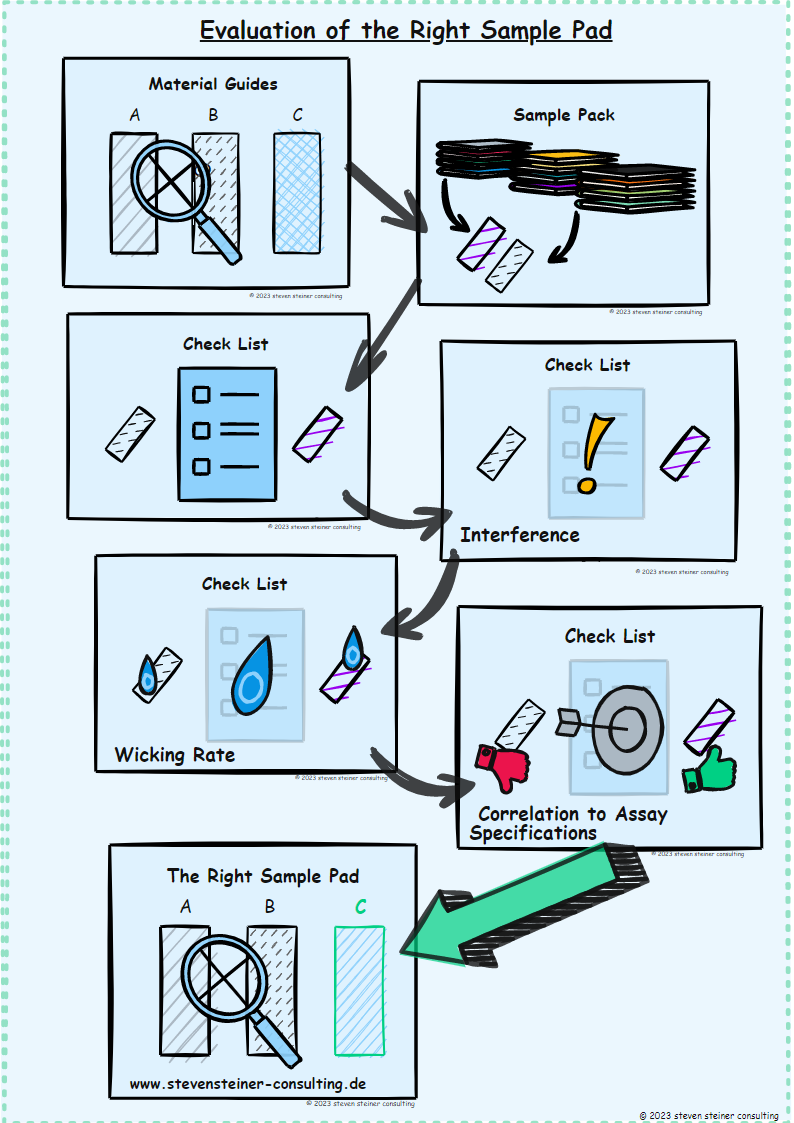

Evaluation of the sample pad

At the start of development of your lateral flow assay you might be overwhelmed by the amount of different sample pad materials available. You should start with the following steps:

- Read the various sample pad guidelines from the well-known manufacturers. Combined with information about your sample matrix you will have already narrowed down the number of usable materials then.

If your matrix is for example whole blood and you need to filter the red blood cells so to get a nice clear background on the membrane your choice of sample pad material is already quite limited.

- Get sample packs from the manufacturers. Before you order big amounts of material that are likely to end in the bin or in some mysterious corner of your storage room ask for a sample pack. They generally contain 5-10 different materials in sheet format. You can then quickly screen different options and chose 2-3 champions for the next step.

- Thoroughly evaluate your selected candidates regarding:

- Size: is the material usable for your test when you apply it to your cassette? If it is too thick it will be crushed or compressed during assembly. This can lead to problematic flow behavior.

- Adhesion: Check if the material is sticking in the desired length to your backing. Nothing more annoying than a lose sample pad. Check the handling also after treatment with your impregnation-solution, if you are going to use this.

- Mechanical stability: If you are going to use reel-to-reel equipment you want your sample pad with a good tensile strength – also after treatment with impregnation solution.

- Performance: Check the performance in your assay. Some pads improve the later flow behavior of your test delivering nice homogeneous test lines. Others might interfere with your assay. Keep in mind that there could be additives in the pad material, that interact with your analyte or its ability to bind to the capture antibodies – so check for interferences.

- Wicking rate: Earyl on you want also to evaluate how fast your sample is taken up by the pad and if the capacity of the pad is sufficient for sample plus running buffer.

These are only some ideas on the necessary evaluation tests. You should correlate the materials’ properties to the requirement specifications of your assay. For example, if the requirement is to have a very fast test result, then you would probably not use a sample pad that takes minutes to soak up your sample.

You can find a good short guide for choosing the the right sample pad for your specific application also here:

https://www.abingdonhealth.com/how-to-select-the-most-appropriate-sample-pad/

Conclusion

In conclusion, the sample pad plays an important role in the functionality and performance of lateral flow tests. Its ability to absorb, prepare, transport, and filter the sample is determining the overall success of the test. The choice of material, its thickness, density, pore size, and surface chemistry can significantly affect the performance of the sample pad and, consequently, the test results.

The application process of the sample pad, including its pre-treatment or coating with different substances, is also a critical factor in its performance. The evaluation of the sample pad, including its size, adhesion, mechanical stability, and performance in the assay, is an essential step in the development of a lateral flow assay.

While the sample pad may seem like a simple component, its design and function are complex and require careful consideration and evaluation. The choice of the right sample pad material, its proper manufacturing, and thorough evaluation can significantly enhance the performance of a lateral flow test, leading to more accurate and reliable results.

References

[1] Posthuma-Trumpie GA, Korf J, van Amerongen A. Lateral flow (immuno)assay: its strengths, weaknesses, opportunities and threats. A literature survey. Anal Bioanal Chem. 2009;393(2):569-582.

[2] O'Farrell, B. (2009). Lateral flow immunoassay systems: evolution from the current state of the art to the next generation of highly sensitive, quantitative rapid assays. In The Immunoassay Handbook (pp. 89-107). Elsevier.

[3] Eltzov, E., Guttel, S., Low Yuen Kei, A., Sinawang, P.D., Ionescu, R.E. and Marks, R.S. (2015), Lateral Flow Immunoassays – from Paper Strip to Smartphone Technology. Electroanalysis, 27: 2116-2130.

If you need further assistance or consultation, don't hesitate to reach out to me.

Don’t hesitate to contact me and book a meeting.

Share your own experiences, ideas, or challenges related to lateral flow test cassettes and send me a message.

Disclaimer: All Pictures were produced by AI Bing Image Creator. Sketches were made with SketchWoW.

Lateral Flow Tests (LFTs) have become a household term in recent years, primarily due to their widespread use in rapid diagnostic testing, including COVID-19 antigen tests. These tests, known for their simplicity, speed, and cost-effectiveness, have revolutionized the field of point-of-care diagnostics, enabling quick and accurate detection of various diseases and conditions.

Lateral Flow Tests (LFTs) have become a household term in recent years, primarily due to their widespread use in rapid diagnostic testing, including COVID-19 antigen tests. These tests, known for their simplicity, speed, and cost-effectiveness, have revolutionized the field of point-of-care diagnostics, enabling quick and accurate detection of various diseases and conditions.