A Balanced View: Pros and Cons of Outsourcing Lateral Flow Test Production

Introduction

Lateral flow tests have become an indispensable tool in the life sciences industry. They offer quick and reliable diagnostics for a myriad of conditions. Ever wondered how those handy lateral flow tests are made? It's a complex dance of science and logistics. This blog post aims to be your guide through this exciting ballet, examining the pros and cons of in-house vs. outsourced manufacturing.

Objective

So, why should you read this? By the end, you'll have a 360-degree view of the manufacturing landscape of lateral flow tests, empowering you to make informed decisions for your own needs.

1. Preparatory Processes

Processes Included:

In-House vs. Outsourcing

Imagine you're a chef. Would you prefer to grow your own ingredients or buy them from a trusted s upplier? Both have their merits and drawbacks.

upplier? Both have their merits and drawbacks.

In-House

|

Pros

|

Cons

|

|

Customization: Greater control over the final product.

|

High Costs: Significant investment in equipment and skilled personnel.

|

|

Quality Assurance: Direct oversight ensures quality.

|

Resource Drain: Managing these processes can divert focus from other critical aspects.

|

|

Intellectual Property: Minimized risk of information leakage.

|

Scalability Issues: Scaling up may require additional time and investment.

|

Outsourcing/Commercial Source

|

Pros

|

Cons

|

|

Cost-Effectiveness: More economical for smaller operations.

|

Quality Risks: Dependent on the service provider's quality control.

|

|

Expertise: Access to specialized knowledge.

|

IP Vulnerability: Risk of proprietary information being compromised.

|

|

Time Efficiency: Faster time-to-market.

|

Dependency: Delays from the service provider can impact your timelines.

|

The decision to manage antibody preparation in-house or to outsource it depends on various factors such as cost, quality control, and strategic focus. Both approaches depend on the specific needs and capabilities of your organization.

Expert Tips:

- Albeit you have already the processes and equipment for antibody preparation on site you should definitely look for an external specialized service provider. Make sure to sign on a well-established company and install a supply agreement rather sooner than later.

- The same is true for the antibody labeling if needed. Many antibody suppliers often also provide specialized labeling services. So why not getting the complete package? Especially as a small company this can save you major headaches.

- The detection particle topic is a very special topic and for some companies it is kind of a matter of faith. Generally, if you are going to use gold or latex particles anyway, then you can definitely rely rather on commercial sources of well-known big players. Safe time, money and resources before setting up your own particle synthesis unit. However, if you have developed a very specialized process or technology and may also consider to sell your particles as a stand-alone product, then go for it!

2. Detection Particle Processes

Processes Included:

Detection Particle Coating

Detection Particle Conjugation

Buffer Preparation

In-House vs. Outsourcing:

Think of this as the  seasoning in a dish. Get it wrong, and the whole thing falls flat.

seasoning in a dish. Get it wrong, and the whole thing falls flat.

In-House

|

Pros

|

Cons

|

|

Precision: Direct control allows for fine-tuning of coatings.

|

Technical Complexity: Requires specialized equipment and expertise.

|

|

Quality Consistency: In-house processes can ensure uniformity across batches.

|

Resource Allocation: May necessitate hiring or training specialized staff.

|

|

Rapid Adaptability: Easier to implement changes based on real-time quality checks.

|

Regulatory Hurdles: In-house processes may face stricter regulatory scrutiny.

|

Outsourcing

|

Pros

|

Cons

|

|

Cost Savings: No need for in-house equipment and specialized staff.

|

Quality Variability: Risk of inconsistencies between batches.

|

|

Access to Innovation: Benefit from the service provider's R&D efforts.

|

Limited Customization: May have to work within the service provider's existing capabilities.

|

|

Focus on Core Activities: Frees up internal resources for other key areas.

|

Communication Barriers: Potential for misunderstandings or delays in implementing changes.

|

Most of the companies that I have worked with pride themselves on their sophisticated coating an immobilization processes. And the truth is, that the coating, immobilization and blocking of the detection particles is almost always specially tailored and fine-tuned to your specific assay and this is most often done during the development of the test.

Expert Tip: Some companies specialize in these steps. They're like the spice merchants of old, offering exotic flavors you didn't even know you needed.

It is worthwhile noticing that

- There are companies available that solely focus on the optimization of these steps, are experts in this field and use most often some kind of patented technology that can give you the edge over your competitors.

- Most of those companies also offer processes, where to a later time point the outsourced procedures can be transferred and installed at your site.

The topic “buffer preparation” was treated shabby in this section – and this with good reason. There is from point of view of a chemist no real benefit from outsourcing this process or use of premixed buffers. The running buffers most probably will need to be fine-tuned to your specific assay and you really want to be in charge of ingredients and composition – as this is also easily controllable by yourself. The same is true for the dispensing and impregnation buffers. So better buy and mix the salts and other raw materials by yourself.

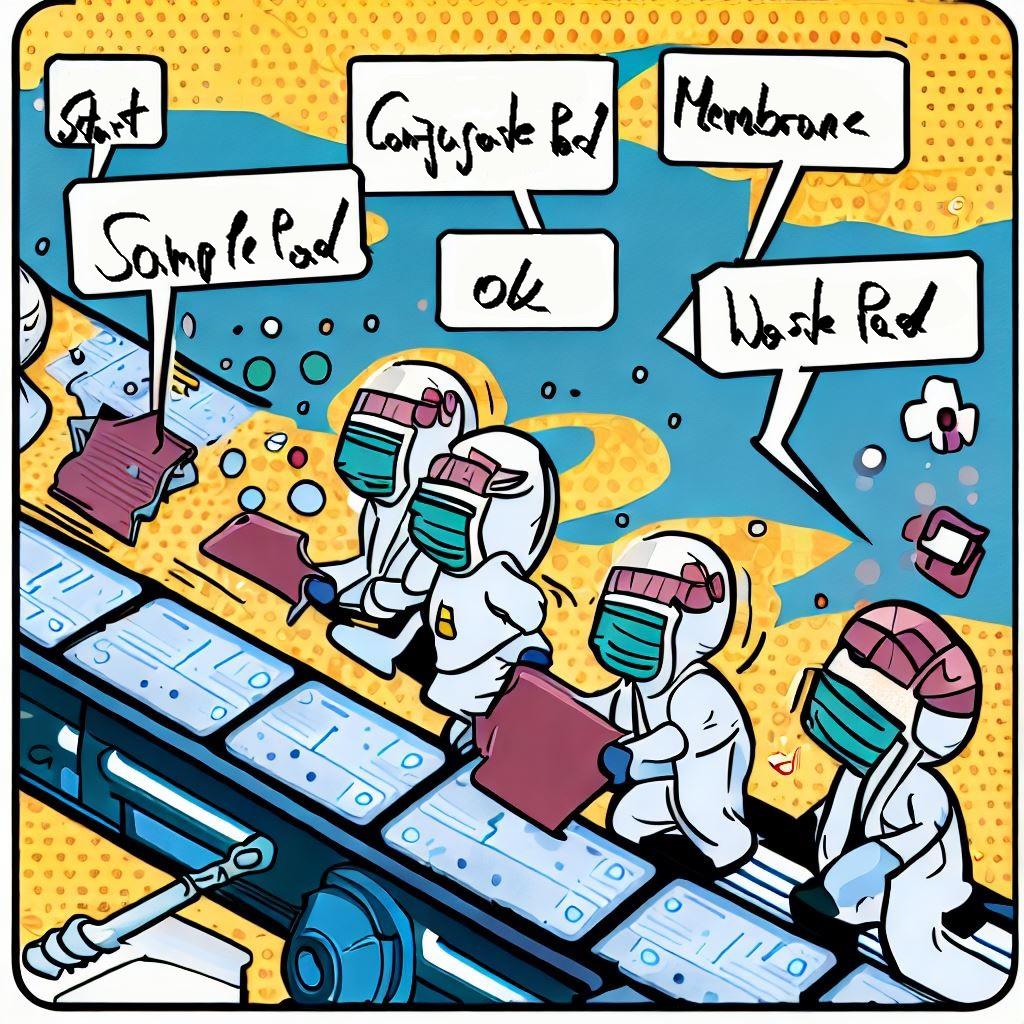

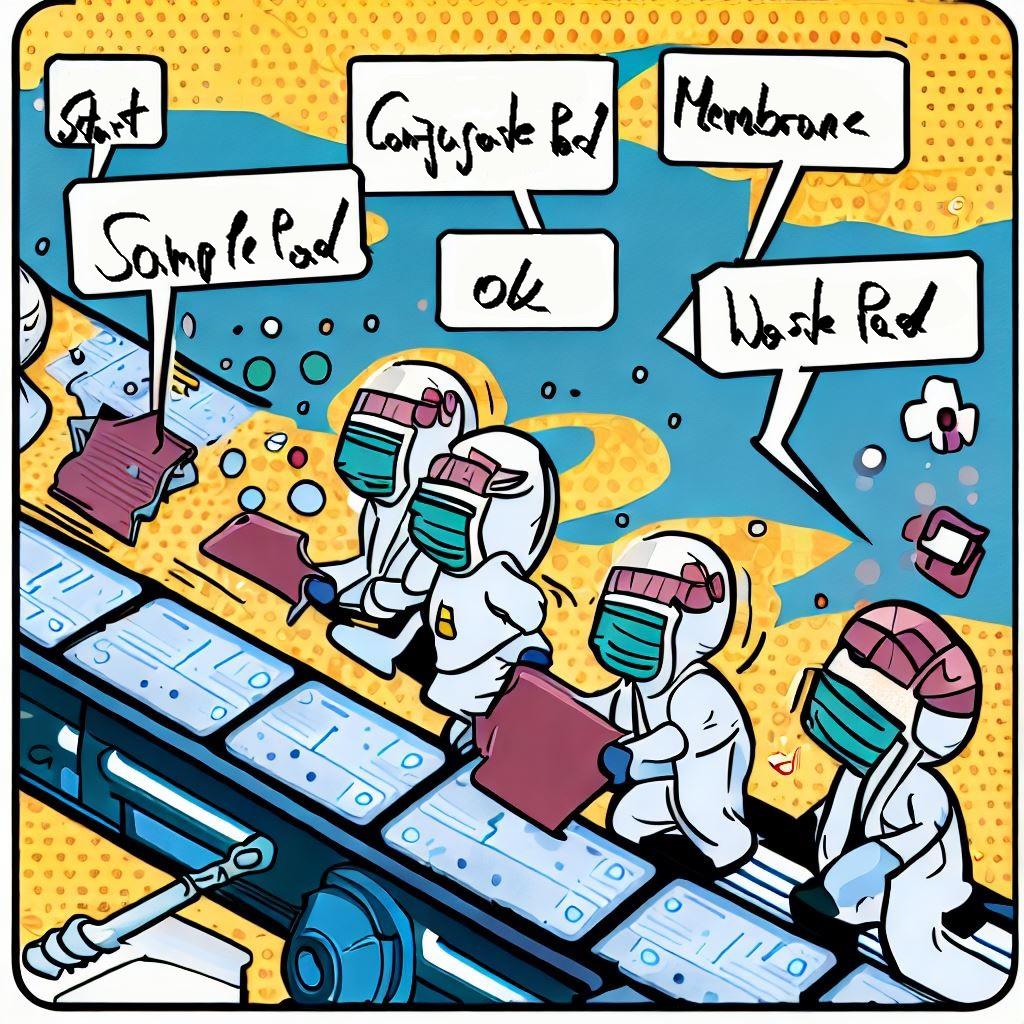

3. Material Treatment and Assembly

Processes Included:

In-House vs. Outsourcing:

This is where the rubber meets the road, or rather, where the components come together to form a functional test.

This is where the rubber meets the road, or rather, where the components come together to form a functional test.

In-House

|

Pros

|

Cons

|

|

Integrated Quality Control: Easier to maintain consistency when all steps are managed in-house.

|

Logistical Complexity: Requires careful coordination of multiple steps.

|

|

Flexibility: Allows for on-the-fly adjustments to the assembly process.

|

High Overheads: Costs for storage, labor, and quality checks can add up.

|

|

Confidentiality: Reduced risk of design or process leaks.

|

Limited Throughput: May face bottlenecks if demand suddenly increases.

|

Outsourcing

|

Pros

|

Cons

|

|

Economies of Scale: Service providers may offer cost benefits for large-scale production.

|

Quality Assurance: Reliant on the service provider's quality checks.

|

|

Specialized Expertise: Access to specialized assembly techniques.

|

Limited Oversight: Less control over the intricate details of assembly.

|

|

Reduced Lead Time: Faster time-to-market due to streamlined processes.

|

Contractual Constraints: May face limitations based on contractual agreements.

|

Expert Tip: Outsourcing can be a win-win. It's like a relay race where each runner specializes in a different terrain.

From my experience this kind of outsourcing in a variety of scenarios is a very common step in diagnostic industry. There is a good win-win scenario for both parties in that the diagnostic company doesn’t need to invest in costly manufacturing equipment and special trained personnel. The contractor on the other hand has a good plannable occupancy rate of his machines.

Common scenarios:

|

Scenario

|

Deliverable Customer

|

Deliverable Contractor

|

|

1

|

Liquids (Detection-Conjugate, Capture antibody, Blocking Solution)

|

- Sprayed and Lined Assembled Reels or assembled Cards

- Completely packed Lateral Flow Tests (Strip in Cassette in Pouch)

|

|

2

|

Lined blocked Membrane and Conjuagte Pad on reels

|

- Assembled Reels or assembled Cards

- Completely packed Lateral Flow Tests (Strip in Cassette in Pouch)

|

|

3

|

Sprayed and Lined Assembled Reels or assembled Cards

|

Completely packed Lateral Flow Tests (Strip in Cassette in Pouch)

|

4. Cassette Assembly and Primary Packaging

Processes Included:

In-House vs. Outsourcing:

Picture this as the final presentation of a gourmet dish. The taste is crucial, but so is the presentation.

Picture this as the final presentation of a gourmet dish. The taste is crucial, but so is the presentation.

The cassette assembly and primary packaging stages are crucial for the user experience and the test's overall reliability. It is not too uncommon (as already shown in section 3) that assembled cards or reels are transferred to an external partner for cassette assembly and packaging.

In-House

|

Pros

|

Cons

|

|

Brand Consistency: Easier to ensure that all packaging aligns with brand guidelines.

|

Storage Requirements: Need for adequate storage space for assembled cassettes.

|

|

Quality Control: Direct oversight of the final product before it goes to market.

|

Labor Costs: May require additional staff for assembly and packaging.

|

|

Quick Modifications: Ability to make last-minute changes to packaging or labeling.

|

Complexity: Managing multiple SKUs can become challenging.

|

Outsourcing

Pros

|

Cons

|

|

Cost-Effectiveness: Potential for lower costs due to economies of scale.

|

Quality Risks: Dependent on the service provider's quality control measures.

|

|

Speed: Faster turnaround times for large batches.

|

Limited Customization: May have to work within the service provider's capabilities.

|

|

Resource Allocation: Frees up internal resources for R&D or other core activities.

|

Logistical Challenges: Need to coordinate shipping and receiving of assembled cassettes.

|

Expert Tip: These processes are most often outsourced when your manufacturing scale is sufficiently large enough to manufacture at least in a scale of several hundreds of master-cards and manual cassette assembly is getting too costly – but you have not reached the point for investing in a small automatic cassette assembler with connected pouching machine.

It's akin to hiring a professional plating artist for a high-end restaurant.

5. Kit Assembly and Final Packaging

Processes Included:

-

Kit Assembly

- Packaging

- Intermediate Storage and Shipping

In-House vs. Outsourcing:

This is the final bow after a grand performance. The applause is great, but what about the encores?

This is the final bow after a grand performance. The applause is great, but what about the encores?

The kit assembly and final packaging stages are (often) the last steps at the manufacturer before the product reaches the end-user. These stages are critical for ensuring product integrity and user satisfaction.

In-House

|

Pros

|

Cons

|

|

Full Control: Complete oversight of the final product, ensuring it meets all quality standards.

|

Storage Costs: Requires sufficient storage space for completed kits.

|

|

Inventory Management: Easier to manage stock levels and respond to market demand.

|

Logistical Complexity: Managing shipping and storage can be challenging.

|

|

Shipping Flexibility: More control over shipping options and timelines.

|

Resource Intensive: May require dedicated staff for these final stages.

|

Outsourcing

|

Pros

|

Cons

|

|

Economies of Scale: Potential cost savings for large-scale production.

|

Quality Assurance Risks: Reliant on the service provider's quality control.

|

|

Streamlined Process: Outsourcing can simplify complex logistical tasks.

|

Limited Control: Less influence over shipping methods and timelines.

|

|

Focus on Core Activities: Allows internal teams to focus on R&D and marketing.

|

Contractual Limitations: May be bound by the terms of service agreements, affecting flexibility.

|

Kit-Assembly, i.e. putting all the test components into the kit box and the eventually needed labeling processes are most often still very manual or only half automated processes that require a decent amount of costly personnel and assembly space.

Expert tip: There are a few options how to outsource – and I want to draw your attention to an outsourcing with social impact: sheltered workshop. I have transferred several kit assembly processes to those workshops and was always amazed by the enthusiasm, quality of work and proactive culture at those places.

Of course, as with all outsourcing activities, you have to implement a meaningful Quality Control of all materials that you receive from your contractor before you release them to the market.

Comparative Analysis

In the journey of manufacturing lateral flow tests, each stage presents its unique set of challenges and opportunities. Whether to manage these processes in-house or to outsource them often boils down to a few key factors:

- Cost-Effectiveness: Outsourcing generally offers economies of scale but may compromise on customization and quality control.

- Quality Control: In-house manufacturing allows for stringent quality checks but can be resource-intensive.

- Speed to Market: Outsourcing can expedite the production timeline, but you're dependent on another company's schedule – so comes at cost of flexibility.

- Flexibility and Scalability: In-house processes offer more control and adaptability but may face challenges in scaling up quickly.

- Streamlined and Efficient Processes: Both in-house and outsourced options can offer efficiency gains, but the level of streamlining may vary based on expertise and specialization.

In sum, there are process that can easily be outsourced like Kit assembly and packaging but other better remain under your direct control.

Conclusion

The decision isn't black and white. It's a spectrum of grays, each with its own set of challenges and rewards. Your choice will ultimately depend on your organization's specific needs, capabilities, and strategic goals.

Call to Action

So, what's your take on this? Feel free to reach out. I can connect you to reliable external partners. Let's continue the conversation! Book a meeting.

Disclaimer: All Pictures in this article where created with the aid of Bing Image Creator

upplier? Both have their merits and drawbacks.

upplier? Both have their merits and drawbacks. seasoning in a dish. Get it wrong, and the whole thing falls flat.

seasoning in a dish. Get it wrong, and the whole thing falls flat. This is where the rubber meets the road, or rather, where the components come together to form a functional test.

This is where the rubber meets the road, or rather, where the components come together to form a functional test. Picture this as the final presentation of a gourmet dish. The taste is crucial, but so is the presentation.

Picture this as the final presentation of a gourmet dish. The taste is crucial, but so is the presentation. This is the final bow after a grand performance. The applause is great, but what about the encores?

This is the final bow after a grand performance. The applause is great, but what about the encores?