Guide to Cassette Selection or Design for Lateral Flow Test Development and Manufacturing

Introduction

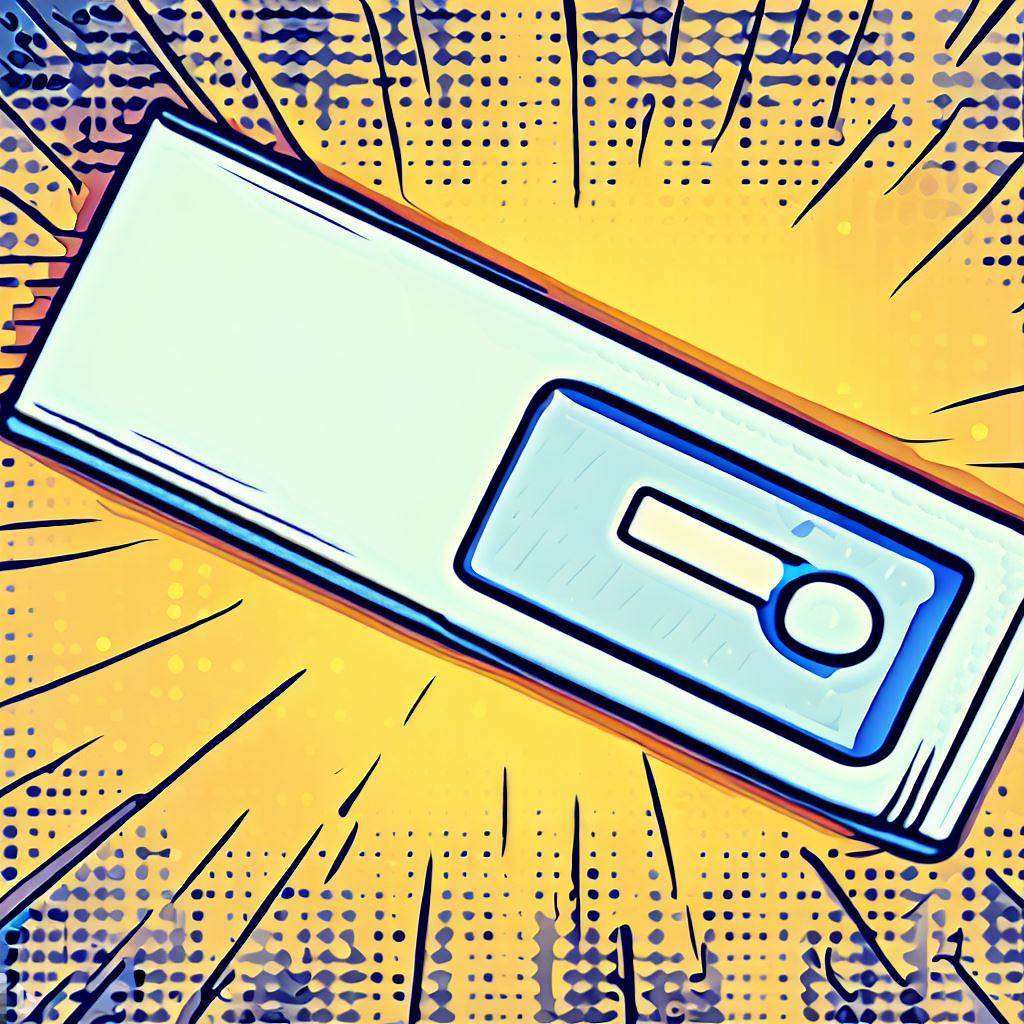

Imagine holding the key to significantly enhancing the performance, reliability, and usability of lateral flow tests. That key is the cassette - the protective housing that not only safeguards the test strip but also provides a user-friendly interface for sample application, result interpretation, and data capture. The right cassette selection or design can be a game-changer, and even the exterior design can be leveraged to create brand awareness for your lateral flow tests. However, it's worth noting that a unique exterior design might pose challenges at your CDMO if it doesn't align with standard processes and available equipment.

If you're keen on delving into the intricacies of cassette selection and design for lateral flow tests, you've come to the right place. Whether you're seeking a suitable cassette for your specific test as a potential customer, aiming to optimize your cassette design as a professional in the field, or simply a student wanting to grasp the fundamentals of cassette engineering, this blog post is tailor-made for you. Within these pages, we will provide you with valuable insights, tips, and expert guidance.

PART 1: Understanding and Selecting Lateral Flow Test Cassettes

In this first part of our guide, we learn about

- cassette selection and design for lateral flow tests,

- the primary functions and components of a cassette,

- different types of cassettes,

- and the factors to consider when selecting or designing a cassette.

This part is particularly useful for those seeking a suitable cassette for a specific test, professionals aiming to optimize their cassette design, or students wanting to grasp the fundamentals of cassette engineering.

“In the world of lateral flow tests, the cassette is more than just a container. It's a carefully designed component.”

The first section will guide you through the two primary categories of cassettes: standard cassettes, which are widely used due to their accessibility and costs, and non-standard cassettes, which offer tailored solutions for specific requirements, advanced operations and marketing.

1. The Role of Standard Cassettes

Standard cassettes are the corn erstone of lateral flow tests, providing a protective shell for the test strip and a user-friendly interface for sample application and result interpretation. These cassettes are tailored to house the specific components required for the test, such as the sample pad, conjugate pad, reaction membrane, and absorbent pad. The cassette, typically made of plastic, secures the test strip and ensures its proper alignment.

erstone of lateral flow tests, providing a protective shell for the test strip and a user-friendly interface for sample application and result interpretation. These cassettes are tailored to house the specific components required for the test, such as the sample pad, conjugate pad, reaction membrane, and absorbent pad. The cassette, typically made of plastic, secures the test strip and ensures its proper alignment.

The defining features of standard cassettes are their simplicity, user-friendliness, and compatibility with automated manufacturing processes. They are extensively used in a variety of lateral flow assays, including pregnancy tests, infectious disease diagnostics, and drug testing kits.

1.1 Advantages and Applications of Standard Cassettes

Standard cassettes have been a mainstay in the field of lateral flow tests for several decades, offering readily available solutions with a proven track record. They are cost-effective due to their mass production and availability from commercial suppliers, making them an affordable option for test developers and manufacturers. This accessibility makes them ideal for large-scale production and distribution or for cases of emergency productions like during the COVID-19 pandemic.

Standard cassettes have undergone rigorous testing and optimization, ensuring their reliability and robustness. They have been widely used in numerous lateral flow test applications, leading to a thorough understanding of their performance characteristics and limitations. Test developers can leverage this existing knowledge and experience to accelerate their own test development process.

However, standard cassettes do have some limitations. As they are not specifically designed for a particular lateral flow test, they may lack optimization for certain requirements, such as sensitivity or sampling capacity. Each lateral flow test has unique parameters and may benefit from customized cassette designs that maximize performance. Additionally, standard cassettes may not incorporate the latest advancements in design features or materials, potentially impacting their overall performance in certain scenarios.

1.2. Commercially Available Standard Cassettes

Several commercially available standard cassettes cater to the diverse needs of lateral flow test developers and manufacturers. These cassettes are designed to be compatible with a large range of lateral flow tests and offer a reliable platform for sample application and result interpretation.

A good starting point for a search is – quite obviously – https://www.lateralflowcassette.com. But you might maybe also want to look more regionally for example at

But there are many more sources to look at, if necessary.

References:

[1] [Lateral Flow Assay Cassette Design | DCN Dx] (https://dcndx.com/blog/lateral-flow-assay-cassette-design/).

[2] [MilliporeSigma Lateral Flow Test Strips] (https://www.diagnosticsworldnews.com/milliporesigma-lateral-flow-test-strips).

[3] [Natechplastics] (https://natechplastics.com/lateral-flow-cassette/).

[4] [Drummond Sci ] (https://www.drummondsci.com/product/lateral-flow-cassette/lateral-flow-assay-cassette/).

[5] [MDI] (https://mdimembrane.com/plastic-cassettes).

[6] [Kinbio] (https://www.kinbio.com/product/special_packing_material_for_immunochromatography).

[7] [DCN] (https://dcndx.com/blog/lateral-flow-assay-cassette-design/).

[8] [Kenosha Tapes] (https://www.kenoshatapes.com).

2. Non-Standard Cassettes

Non-standard cassettes are not bought off the peg, but are rather customized parts.

These Cassettes are tuned to specific requirements and advanced operations. Unlike standard cassettes, which offer a one-size-fits-all solution, non-standard cassettes provide a platform for innovation and optimization. They are tailored to

- accommodate specialized test components (for example integrated liquid or reagent reservoirs),

- advanced sample handling mechanisms (for example directly attached extraction or enrichment devices),

- integrated microfluidic channels,

- or simply to accommodate a specific lateral flow test setup

offering greater flexibility and customization.

Non-standard cassettes are important for advanced operations that demand enhanced performance, sensitivity, or unique functionalities. They enable complex sample pre-processing, such as sample filtration, concentration, or enrichment, within the cassette itself. They can incorporate advanced features like multiplexing, enabling the simultaneous detection of multiple analytes in a single test. Additionally, non-standard cassettes may include integrated sensors or digital interfaces for real-time data capture and analysis, enhancing the overall capabilities of the lateral flow test.

2.1. Exploring the Potential of Non-Standard Cassettes

While standard cassettes are the go-to solution for many lateral flow test applications, there are instances where a more tailored approach is required.

Non-standard cassettes are solution to assays that demand enhanced performance, sensitivity, or unique functionalities. They accommodate specialized test components, advanced sample handling mechanisms, or integrated microfluidic channels. This flexibility and customization allow test developers to optimize their assays for specific applications.

In advanced lateral flow operations, non-standard cassettes can enable complex sample pre-processing, such as sample filtration, concentration, or enrichment, within the cassette itself. They can incorporate advanced features like multiplexing, enabling the simultaneous detection of multiple analytes in a single test. Additionally, non-standard cassettes may include integrated sensors or digital interfaces for real-time data capture and analysis, enhancing the overall capabilities of the lateral flow test.

2.2. Case Studies and the Role of Specialized Plastics

Non-standard cassettes have been instrumental in advancing lateral flow testing by offering tailored solutions to specific applications. Let's explore a couple of case studies that highlight the benefits and specific applications of these advanced cassettes.

- The Multiplex Odexxo device is an all-in-one lateral flow test device that allows for the simultaneous detection of multiple analytes in a single test. This multiplexing capability is particularly useful in situations where multiple potential diagnoses need to be ruled out.

- Another example is the Bloom Diagnostics Cassette. It is specifically designed to be used with the Bloom Lab reader and is employed in a point-of-care testing setting. It facilitates objective result interpretation, reduced user subjectivity, and enabled automated data capture for real-time analysis and data record integration.

The development of non-standard cassettes often requires the expertise of specialized plastics designers. Companies like Sanner or Teufel offer comprehensive solutions for the development and manufacturing of diagnostic devices, including lateral flow test cassettes. Their expertise in plastics processing and high-precision injection molding enables the production of complex, custom-designed cassettes that meet specific test requirements.

References:

[1] Phangwipas, P.; Thangavel, B.; Shin, J.H. Automated Multistep Lateral Flow Immunoassay Using a Smartphone for the Quantification of Foodborne Bacteria from Fresh Lettuce. Chemosensors 2023, 11, 36.

[2] Eltzov, E., Guttel, S., Low Yuen K2ei, A., Sinawang, P.D., Ionescu, R.E. and Marks, R.S. (2015), Lateral Flow Immunoassays – from Paper Strip to Smartphone Technology. Electroanalysis, 27: 2116-2130.

[3] Erin M. Fenton, Monica R. Mascarenas, Gabriel P. López, and Scott S. Sibbett, ACS Applied Materials & Interfaces 2009 1 (1), 124-129.

[4] Tassaneewan Laksanasopin et al. ,A smartphone dongle for diagnosis of infectious diseases at the point of care.Sci. Transl. Med.7,273re1-273re1(2015).

[5] Yu, S., Sun, W., Zhang, P. et al. High Sensitive Visual Protein Detection by Microfluidic Lateral Flow Assay with On-Stripe Multiple Concentration. Chromatographia 83, 1145–1151 (2020).

[6] [Odexxo] (https://odexxo.com/home).

[6] [Bloom Diagnostic] (https://bloomdiagnostics.com/technology/).

[7] [Sanner Group] (https://www.sanner-group.com/next-generation-device-cdmo/diagnostic-devices).

[8] [Teufel Prototypen] (https://www.teufel-prototypen.de/de/).

3 Sources

3.1. Commercial Providers: Key to Accessing Diverse Cassette Designs

Commercial providers are instrumental in the lateral flow test industry, offering a variety of cassette designs that can be readily integrated into assay development projects. These designs, often based on standard formats, allow test developers to bypass the initial design phase and focus on optimizing their assays – also towards the selected standard plastic device.

into assay development projects. These designs, often based on standard formats, allow test developers to bypass the initial design phase and focus on optimizing their assays – also towards the selected standard plastic device.

Selecting a provider involves careful consideration of their

- industry reputation,

- product range,

- manufacturing capabilities and,

- quality control processes.

See above for examples of notable and reliable providers.

3.2. In-House Design and Manufacturing: A Tailored Approach

In-house cassette design and manufacturing can offer several benefits, including but not limited to:

- greater control over the design process,

- cost-effectiveness and

- improved inventory management.

However, this approach requires and is also not limited to:

- specialized expertise,

- specialized equipment and

- significant investment for setting up in-house processes.

Key considerations for in-house production include access to skilled personnel, investment in appropriate equipment and infrastructure, and the establishment of a robust quality control system. It's also important to maintain a controlled environment to ensure the integrity and consistency of the cassette production process.

and the establishment of a robust quality control system. It's also important to maintain a controlled environment to ensure the integrity and consistency of the cassette production process.

Regulatory compliance is another critical aspect of in-house production. This includes adherence to ISO standards, such as ISO 13485 for medical device manufacturing, understanding the regulatory pathways for your target market, and maintaining thorough documentation throughout the design and manufacturing process.

References:

[1] [Lateral Flow Assay Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021 - 2026)](https://www.mordorintelligence.com/industry-reports/lateral-flow-assay-market)

[2] Hsiao WW, Le TN, Pham DM, Ko HH, Chang HC, Lee CC, Sharma N, Lee CK, Chiang WH. Recent Advances in Novel Lateral Flow Technologies for Detection of COVID-19. Biosensors (Basel). 2021 Aug 25;11(9):295.

[3] https://scitechconnect.elsevier.com/wp-content/uploads/2014/03/main-18.pdf

Conclusion

In this first part of the guide, we've explored the world of lateral flow test cassettes. We've learned about the role of cassettes in enhancing the performance, reliability, and usability of lateral flow tests. We've also highlighted how the right cassette selection or design can significantly impact the success of your lateral flow test development and manufacturing.

We've also discussed the two primary categories of cassettes: standard and non-standard. Standard cassettes, with their simplicity, user-friendliness, and compatibility with automated manufacturing processes, serve as the cornerstone of many lateral flow tests. On the other hand, non-standard cassettes offer a platform for innovation and optimization, accommodating specialized test components, advanced sample handling mechanisms, or integrated microfluidics.

We've also touched upon the importance of selecting the right commercial providers or considering in-house design and manufacturing. Each approach has its benefits and considerations, and the choice largely depends on your specific requirements, resources, and expertise.

The journey of selecting or designing the right cassette for your lateral flow test can be complex and challenging. However, with the insights and guidance provided in this blog post, I hope to have simplified this process for you. Remember, the cassette is more than just a container - it's a carefully designed component that can make or break your lateral flow test.

As I conclude this part, I encourage you to reflect on these factors when choosing or designing cassettes for your projects. And remember, you're not alone in this journey. If you need further assistance or consultation, don't hesitate to reach out to me.

Don’t hesitate to contact me and book a meeting.

Share your own experiences, ideas, or challenges related to lateral flow test cassettes and send me a message.

erstone of lateral flow tests, providing a protective shell for the test strip and a user-friendly interface for sample application and result interpretation. These cassettes are tailored to house the specific components required for the test, such as the sample pad, conjugate pad, reaction membrane, and absorbent pad. The cassette, typically made of plastic, secures the test strip and ensures its proper alignment.

erstone of lateral flow tests, providing a protective shell for the test strip and a user-friendly interface for sample application and result interpretation. These cassettes are tailored to house the specific components required for the test, such as the sample pad, conjugate pad, reaction membrane, and absorbent pad. The cassette, typically made of plastic, secures the test strip and ensures its proper alignment.

into assay development projects. These designs, often based on standard formats, allow test developers to bypass the initial design phase and focus on optimizing their assays – also towards the selected standard plastic device.

into assay development projects. These designs, often based on standard formats, allow test developers to bypass the initial design phase and focus on optimizing their assays – also towards the selected standard plastic device. and the establishment of a robust quality control system. It's also important to maintain a controlled environment to ensure the integrity and consistency of the cassette production process.

and the establishment of a robust quality control system. It's also important to maintain a controlled environment to ensure the integrity and consistency of the cassette production process.